An Industry Report: The Hidden Costs of Poor ERP Implementation in Manufacturing

By Remington Leland, Consultant

Introduction

Why ERP Matters in Manufacturing

Modern manufacturing requires synchronized operations and immediate access to reliable data. ERP systems support this by integrating production, inventory, finance, compliance, and other core functions. However, implementation missteps—ranging from misaligned configurations to insufficient training—can render even the best systems ineffective.

This report details the financial, operational, and strategic costs associated with poor ERP implementations. Drawing from industry benchmarks and practical experience, it outlines the risks and offers actionable steps to improve outcomes.

1. Financial Costs: Wasted Investment and Hidden Expenses

Underutilized Functionality

Up to 60% of ERP functionality remains unused in many manufacturing environments due to insufficient training and poor configuration.1 This underutilization represents a direct waste of capital investment and impedes return on investment (ROI).

Labor Inefficiencies

When ERP systems are not properly implemented, manual workarounds become the norm. Manufacturers frequently report a 15% increase in labor costs linked to redundant tasks and inefficient workflows.2

Redundancy and Fragmented Data

Roughly 70% of manufacturers continue using spreadsheets and disconnected tracking tools even after ERP deployment.3 This parallel system usage leads to data inconsistency, manual entry errors, and increased time spent reconciling records.

2. Operational Costs: Disruption, Delay, and Downtime

Inventory and Supply Chain Volatility

ERP systems that fail to accurately track inventory and supplier data introduce uncertainty. This results in excess stock, shortages, and supply chain bottlenecks that directly impact production timelines.

Scheduling Failures

ERP-driven scheduling is only effective if the system is correctly set up and trusted by operations staff. Without this, production delays, bottlenecks, and missed delivery targets become routine.

Lack of Real-Time Insight

Disconnected data silos limit leadership’s ability to make timely decisions. When financial and operational data aren’t aligned within a single ERP environment, the agility needed to respond to market shifts is lost.

3. Strategic Costs: Long-Term Competitive Risks

Growth Constraints

Poor ERP architecture often limits a company’s ability to scale. In fact, 40% of manufacturers cite ERP system limitations as a direct barrier to expansion into new markets or facilities.4

Low Adoption and Change Fatigue

ERP usability is critical to adoption. Organizations that fail to prioritize user training and change management see adoption rates drop by up to 30%, reinforcing resistance and diminishing ROI.5

Missed Automation and AI Integration

Many manufacturers are unable to leverage AI, machine learning, or even basic automation due to legacy system limitations or flawed ERP setups.6 This technological stagnation prevents companies from achieving efficiency gains or future-proofing their operations.

Compliance Failures: The ITAR Example

For industries governed by strict regulations (e.g., aerospace and defense), a misconfigured ERP system poses serious risks. Without proper access controls, audit trails, and document management protocols, compliance with standards such as International Traffic in Arms Regulations (ITAR) becomes unreliable, exposing companies to fines, legal liability, and reputational damage.7

4. Best Practices for ERP Implementation in Manufacturing

Prioritize Training and Change Management

ERP adoption correlates directly with the depth and frequency of user training. A structured, role-specific training program ensures that users not only understand system functionality but also apply it correctly within workflows.

Integrate Across Core Business Systems

ERP systems must connect seamlessly with quoting, production management, accounting, and procurement. Fragmented architectures result in data inconsistencies and decision-making blind spots.

Commit to Continuous Improvement

ERP is not a “set it and forget it” tool. Regular audits, periodic reconfiguration, and end-user feedback loops ensure that the system evolves with business needs and maintains relevance as operations scale.

Conclusion: ERP as Business Infrastructure

ERP implementation is not merely an IT project – it’s a foundational business transformation. The risks of poor execution are real: financial losses, operational breakdowns, and missed strategic opportunities. Conversely, when implemented correctly, ERP becomes a force multiplier for productivity, insight, and resilience.

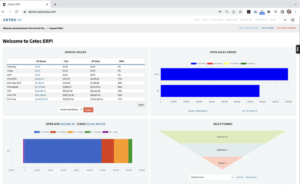

How Cetec ERP Approaches Implementation Differently

Many ERP vendors deliver software but leave manufacturers to navigate implementation alone. Cetec ERP takes a more hands-on approach that emphasizes long-term operational success:

• Partner-Centric Implementation Support: Cetec ERP collaborates closely with third-party implementation partners, providing them with targeted training to ensure best-practice deployment aligned with Cetec’s platform architecture.

• Structured, Paid Training Programs: Training is not an afterthought. Cetec ERP delivers role-specific sessions designed to increase system proficiency and adoption. While training is a paid service, it is essential to realizing system value.

• Built-In Industry-Specific Features: Cetec ERP includes pre-configured tools tailored to the needs of regulated industries such as aerospace, wire harness, and chemicals, minimizing the need for costly customization.

• Secure and Compliant Architecture: Cetec ERP offers robust access controls, document traceability, and secure audit trails, making it easier to comply with standards like ITAR without bolting on third-party solutions.

• Cloud-Native, Continually Optimized: As a native cloud platform, Cetec ERP enables automatic updates and iterative improvements, eliminating the burden of disruptive version upgrades or major overhauls.

If your ERP system creates more friction than it resolves, it’s time to reassess your implementation strategy. Cetec ERP offers manufacturers a more structured, supportive pathway toward ERP success, grounded in practical guidance and operational results.

References:

- Panorama Consulting Group, 2025 ERP Report. https://www.panorama-consulting.com/resource-center/erp-report

- Deloitte, Accessing Skilled Human Capital for the Smart Manufacturing Era, 2024. https://www2.deloitte.com/content/dam/Deloitte/us/Documents/smart-manufacturing-salessheet-2024.pdf

- Aberdeen Group, Why Choosing a Cloud-based ERP Platform Improves Performance, March 2019. https://wp-aberdeen.s3.amazonaws.com/wp-content/uploads/2022/11/10043352/17842-KB-ChooseCloudBasedERP.pdf

- PwC, Digital Factory Transformation Survey 2022. https://www.pwc.de/de/content/0f96ea9c-992c-4ba7-8c4d-b4637cf81d9f/pwc-digital-factory-transformation-survey-2022.pdf

- Forrester Research, Enterprise Resource Planning Market Insights, 2023. https://www.forrester.com/report/enterprise-resource-planning-market-insights-2023/RES179889

- McKinsey & Company, The State of AI in 2023: Generative AI’s Breakout Year. https://www.mckinsey.com/~/media/mckinsey/business%20functions/quantumblack/our%20insights/the%20state%20of%20ai%20in%202023%20generative%20ais%20breakout%20year/the-state-of-ai-in-2023-generative-ais-breakout-year_vf.pdf

- National Institute of Standards and Technology (NIST), SP 800-171 Rev. 3: Protecting Controlled Unclassified Information in Nonfederal Systems and Organizations, May 2024. https://csrc.nist.gov/pubs/sp/800/171/r3/final

For more information about Cetec ERP, contact the company at 1700 Montopolis Dr., Suite E

Austin, TX 78741; 512-299-9170; E-mail: scott@cetecerp.com; Web site: cetecerp.com.