Test Research Inc. Builds Engineering Confidence into Every Test

By Robert Yebra, Global Marketing Dept.

Since 1989, Test Research Inc. (TRI) has played a defining role in the advancement of electronics manufacturing, delivering the test, inspection, and metrology solutions that ensure products perform exactly as intended every time they reach the field. In an industry where the cost of failure is measured in safety risks, warranty exposure, and lost market opportunities, TRI has become synonymous with confidence. Its equipment, engineering expertise, and global support infrastructure form a backbone of reliability for thousands of manufacturers worldwide.

Since 1989, Test Research Inc. (TRI) has played a defining role in the advancement of electronics manufacturing, delivering the test, inspection, and metrology solutions that ensure products perform exactly as intended every time they reach the field. In an industry where the cost of failure is measured in safety risks, warranty exposure, and lost market opportunities, TRI has become synonymous with confidence. Its equipment, engineering expertise, and global support infrastructure form a backbone of reliability for thousands of manufacturers worldwide.

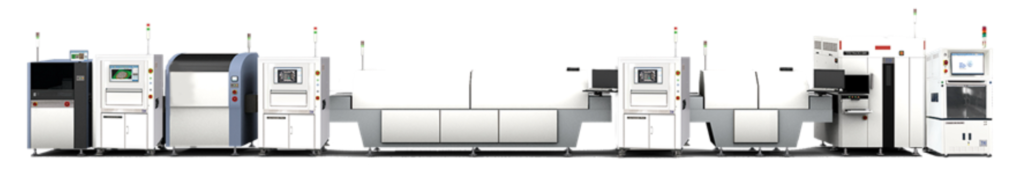

TRI’s trajectory reflects deliberate and sustained investment in engineering excellence. What began as a focused effort to solve fundamental test challenges in circuit manufacturing has grown into a comprehensive portfolio spanning solder paste inspection (SPI), automated optical inspection (AOI), conformal coating AOI, automated X-ray inspection (AXI), semiconductor optical inspection (SEMI AOI), in-circuit test (ICT), manufacturing defects analysis (MDA), wafer metrology, and a smart factory software suite. Across each domain, the company prioritizes innovation in solutions that maximize accuracy, eliminate escapes, and reduce operator workload, all while integrating seamlessly into modern production environments.

As Larry Chen, Marketing Manager at TRI, says, “Our customers operate in environments where downtime, uncertainty, and missed defects carry significant financial consequences. They need systems engineered for the pressures of the factory floor.”

Today, TRI operates as a global leader, with more than 1,000 employees across five continents, over 3,000 customers, more than 50 distributors, and a network of subsidiaries in the United States, Germany, Japan, Korea, Mexico, Malaysia, Vietnam, Thailand, and China. Its headquarters and R&D center in Taipei, along with manufacturing facilities in Northern Taiwan, serve as the nucleus for a company committed to long-term development and rapid customer support. The company’s quality, environmental, safety, and information security practices are validated through industry-leading certifications, including ISO 9001, ISO 14001, ISO 27001, ISO 45001, and SEMI E187.

TRI positions itself not simply as a supplier of inspection systems but as a partner in the realization of robust, manufacturable, high-yield products. The company’s engineering philosophy is grounded in practical problem-solving, designing systems that succeed under production pressures, including high throughput, tight tolerances, demanding board sizes, and continuous runtimes.

“Our role is to turn uncertainty into a documented, repeatable, traceable process,” Chen explains. “When an engineer says they cannot afford another hour of downtime, they’re really asking for solutions designed with their day-to-day realities in mind. That is exactly what we deliver.”

“Our role is to turn uncertainty into a documented, repeatable, traceable process,” Chen explains. “When an engineer says they cannot afford another hour of downtime, they’re really asking for solutions designed with their day-to-day realities in mind. That is exactly what we deliver.”

Customers rely on TRI because the company looks holistically at the entire testing workflow. Beyond delivering precision equipment, TRI provides customization, integration, software development, project management, turnkey test program deployment, field services, and lifecycle support. Its teams are known for working side-by-side with manufacturers to resolve unplanned issues, accelerate deployment, and adapt systems as product designs evolve.

Chen adds, “We treat every customer challenge as a puzzle to be solved, not a ticket to close. Often the best engineering advances come from real-world production conditions because they are tougher and more instructive than any laboratory environment.”

Comprehensive Test and Inspection Portfolio

TRI maintains one of the most extensive product portfolios in the global PCBA and semiconductor inspection market. Its solutions support the full lifecycle of manufacturing verification, from solder paste and component placement to high-density packaging, multilayer assemblies, power modules, and advanced semiconductor devices.

TRI maintains one of the most extensive product portfolios in the global PCBA and semiconductor inspection market. Its solutions support the full lifecycle of manufacturing verification, from solder paste and component placement to high-density packaging, multilayer assemblies, power modules, and advanced semiconductor devices.

Solder Paste Inspection (SPI)

TRI’s SPI platforms deliver high-accuracy, shadow-free 3D inspection with quad-projector imaging, optimized scan paths, closed-loop readiness, and strong gauge R&R. They support applications ranging from fine-pitch micro-bump printing to high-volume networking, server, EV, and consumer electronics.

Automated Optical Inspection (AOI) & Conformal Coating AOI

TRI’s AOI systems combine AI-powered defect classification, multi-angle cameras, metrology-grade accuracy, and multiple 3D technologies to detect solder faults, lifted leads, alignment issues, and dimensional variances. Its conformal coating AOI offers UV-assisted, high-speed inspection with height mapping, thickness measurement, and surface coverage analysis to meet stringent automotive, medical, and aerospace quality requirements.

Automated X-ray Inspection (AXI)

TRI’s AXI systems provide high-resolution 2D, 3D, and CT analysis for dense boards and power electronics. Core capabilities include AI void detection, PTH/THT fill measurement, BGA joint evaluation, and up to 1,000 CT slices, with support for large-format boards up to 2100 x 510 mm.

In-Circuit Test (ICT) & Manufacturing Defects Analysis (MDA)

TRI’s next-generation ICT solutions offer up to 11,088 pins with true 1:1 per-pin architecture, quick-disconnect interfaces, automotive CAN/LIN test support, and integrated LED analysis. Modular MDA platforms provide high-accuracy defect coverage with simple operation and compatibility with robotic handling.

Semiconductor & Advanced Packaging Solutions

TRI supports mid-end and back-end packaging with inspection and metrology for μBump and Cu pillar structures, TSV/TGV, die and wire bonding, thin-film uniformity, and crack or delamination detection. The TR7950Q SII exemplifies this capability with SWIR imaging, EFEM integration, and AI-driven wafer inspection and metrology.

TRI supports mid-end and back-end packaging with inspection and metrology for μBump and Cu pillar structures, TSV/TGV, die and wire bonding, thin-film uniformity, and crack or delamination detection. The TR7950Q SII exemplifies this capability with SWIR imaging, EFEM integration, and AI-driven wafer inspection and metrology.

Smart Factory, AI Ecosystem and Data Intelligence

TRI’s Smart Factory ecosystem enhances inspection with AI-driven programming, parameter optimization, defect detection, and automated repair workflows. Key features include AI defect classification and auto-focus, AI image denoising and inference platforms, automated fine-tuning for AXI and AOI, and centralized AI deployment across multiple lines. The company also supports full Industry 4.0 and M2M connectivity, with capabilities such as:

• Real-time SPC and trend monitoring

• Centralized inspection dashboards

• Automated defect tracking

• Remote alarms and oversight

• Seamless MES and data integration

• YMS 4.0 – Centralized Management System

These solutions enable end-to-end traceability, closed-loop control, and actionable analytics across the production environment.

Chen summarizes this value: “The real power of test and inspection isn’t just the pass-or-fail output, it’s the insight behind it. Data is what drives better yields, faster root-cause analysis, and smarter decision-making across the factory.”

TRI delivers its solutions into markets where failure is not an option:

• Automotive/EV: coplanarity, 3D CT, ECU testing, LED analysis

• Semiconductor and advanced packaging: high-resolution Inspection and metrology and AI defect detection

• Consumer electronics: throughput acceleration and cycle-time reduction

• Telecommunications: high-density boards supporting 5G and AIoT technologies

• Medical devices: traceable metrology for regulatory-grade assemblies

• Aerospace and defense: comprehensive testing for mission-critical electronics

Across these sectors, TRI enables manufacturers to increase yield, reduce scrap, accelerate time-to-market, and preserve product integrity.

Across these sectors, TRI enables manufacturers to increase yield, reduce scrap, accelerate time-to-market, and preserve product integrity.

TRI’s global service infrastructure delivers preventive maintenance, remote diagnostics, on-site technical support, and rapid spare parts provisioning. These operations uphold the company’s core philosophy: reliable systems, predictable performance, and continuous customer success.

“We don’t measure success by how fast a machine leaves our facility,” says Chen. “We measure it by how long it runs invisibly in production – day after day – without drama.”

As electronics become more compact, more complex, and embedded into more aspects of modern life, the need for adaptable, high-precision test solutions intensifies. TRI continues to invest in deep learning, 3D imaging, CT algorithms, high-precision metrology, high-density test architectures, and enterprise-level manufacturing intelligence, all while preserving the customer-first engineering character that has defined the company for more than three decades.

“Engineering is often about tradeoffs,” Chen concludes. “We try to make the right ones, not just the easiest ones. That means designing for the lifetime of the product and the realities of the people who run it.”

For more information about TRI, visit www.tri.com.tw