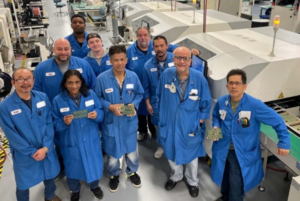

NEOTech Engineers and Manufactures Excellence for High-Reliability Markets

In today’s global marketplace, companies in aerospace, defense, medical, and industrial sectors demand more than just manufacturing capacity; they require a partner who can ensure precision, reliability, and long-term lifecycle support. NEOTech, a leading provider of electronic manufacturing services (EMS), microelectronics, and engineering solutions, has built its reputation on meeting these complex needs. With a proven history of innovation and customer focus, NEOTech is uniquely positioned to serve as a trusted extension of its customers’ engineering and manufacturing teams.

In today’s global marketplace, companies in aerospace, defense, medical, and industrial sectors demand more than just manufacturing capacity; they require a partner who can ensure precision, reliability, and long-term lifecycle support. NEOTech, a leading provider of electronic manufacturing services (EMS), microelectronics, and engineering solutions, has built its reputation on meeting these complex needs. With a proven history of innovation and customer focus, NEOTech is uniquely positioned to serve as a trusted extension of its customers’ engineering and manufacturing teams.

A Legacy of Strength Through Integration

NEOTech was formed through the integration of three established companies: NATEL Engineering, EPIC Technologies, and OnCore Manufacturing. This merger combined decades of expertise in microelectronics, advanced PCB assembly, and global EMS capabilities. The result is an organization with a deep technical foundation and the scale required to meet the needs of both niche high-reliability applications and broader industrial markets.

Headquartered in Chatsworth, CA, the company operates numerous manufacturing sites throughout strategically located countries, which allows NEOTech to serve a diverse portfolio of customers. Importantly, it also provides resilience, ensuring business continuity and flexibility for OEMs in markets where supply chain disruptions and rapid technology shifts are constant challenges.

Diversified Industry Expertise

One of NEOTech’s defining strengths is its balanced industry mix. The company’s revenue is distributed across key high-reliability and industrial sectors:

• Aerospace & Defense (22%) that includes mission-critical systems for air, land, sea, and space.

• Medical (25%) from implantable devices to ophthalmological instruments.

• Industrial (53%) including control and management technologies, semiconductor equipment, power management, and other advanced systems.

This breadth not only minimizes business risk but also drives innovation across sectors. Lessons learned from medical precision, for example, often inform aerospace applications, while industrial automation expertise strengthens NEOTech’s ability to support complex defense programs.

Engineering Beyond Manufacturing

While many EMS providers focus only on production, NEOTech offers a comprehensive suite of engineering and product lifecycle solutions. Its services are designed to fill critical gaps in customers’ technical teams and ensure products are optimized from concept through end-of-life.

While many EMS providers focus only on production, NEOTech offers a comprehensive suite of engineering and product lifecycle solutions. Its services are designed to fill critical gaps in customers’ technical teams and ensure products are optimized from concept through end-of-life.

Engineering Design Services

NEOTech’s engineering experts supplement customer teams, helping with design-for-manufacturing (DFM), design-for-test (DFT), and new product introduction (NPI). This early involvement ensures products are manufacturable, cost-efficient, and reliable before they ever reach the production floor.

Product Lifecycle Extension

As markets evolve and components become obsolete, NEOTech helps OEMs extend the life of their products. Services include redesign for obsolescence mitigation, reverse engineering (such as converting discontinued ASICs to FPGA-based designs), cost reduction, and failure/root cause analysis.

Sustaining Supply Chain Solutions

NEOTech proactively manages component lifecycles, providing alternate sourcing, end-of-life component management, and robust supply chain visibility. This is critical in today’s environment of global component shortages.

NEOTech proactively manages component lifecycles, providing alternate sourcing, end-of-life component management, and robust supply chain visibility. This is critical in today’s environment of global component shortages.

Aftermarket Services

The company also offers repair and refurbishment, ensuring that customers can provide long-term support for their end-users.

Together, these services demonstrate NEOTech’s role as more than just a contract manufacturer. Instead, it serves as a full lifecycle partner, helping customers design, manufacture, sustain, and evolve their products over time.

High-Reliability Manufacturing Capabilities

NEOTech is widely recognized for its ability to manufacture mission-critical components where precision and reliability are paramount. Its facilities support a range of processes, from high-density PCB assemblies to complex microelectronics packaging.

Capabilities include:

• Advanced PCB Assembly: high-complexity, high-density builds (BGA, microBGA, 0201s), SMT, PTH, mixed technology, selective soldering, and rework.

• Microelectronics: chip-and-wire hybrids, multi-chip modules, hermetic packaging, flip chip and CSP attach, and mixed manufacturing (SMT plus chip-and-wire).

• System Integration: complete subsystem and box-build assembly, including RF, analog, and digital systems.

• Test Solutions: AOI, ICT, flying probe, burn-in, RF testing, 2D and 3D X-ray, and full functional/system-level test.

• Unique Processes: conformal coating, press-fit connector assembly, secure premise device programming, and cleanroom capabilities for medical applications.

This technical depth allows NEOTech to serve industries where the margin for error is essentially zero.

Aerospace & Defense: Mission-Critical Expertise

In aerospace and defense, NEOTech has become a trusted partner for OEMs developing systems that lives depend on. The company supports a range of applications:

In aerospace and defense, NEOTech has become a trusted partner for OEMs developing systems that lives depend on. The company supports a range of applications:

Defense: advanced radar, C4ISR systems, ground vehicles, shipboard systems, and robotics.

Aviation: airborne radar, UAVs, flight instrumentation, and commercial aircraft systems.

Space: satellite communications, networking, the International Space Station, Mars Rover, and missile defense programs.

NEOTech’s certifications underscore its credibility in these markets. The company is AS9100-certified, ITAR registered, a DMEA Trusted Foundry, and one of only four companies compliant and with capabilities to manufacture under MIL-PRF-38534 Class H & K. Facilities include Class 10K and 100K clean rooms with ESD and FOD controls, enabling the production of sensitive aerospace components.

Medical: Precision and Compliance

The medical sector requires not only technical expertise but also strict compliance with regulatory standards. NEOTech’s sites are ISO 13485 certified and FDA registered, with dedicated cleanrooms for medical assembly.

Products manufactured include ophthalmological instruments, implantable medical devices, diagnostic systems, and advanced laboratory automation equipment. With the ability to manage rigorous process validation, NEOTech helps its customers bring safe, effective medical technologies to market with confidence.

Industrial: Driving Innovation and Flexibility

In the industrial sector, NEOTech supports a range of applications, from smart energy systems to automotive diagnostic tools and warehouse robotics. Its sites offer flexibility to handle demand volatility, with services extending to repair depots and aftermarket support.

NEOTech’s ability to support both high-mix, low-volume builds and higher-volume production gives it an edge in industrial markets where demand can shift rapidly.

A Customer-Centric Model

NEOTech’s success is built not just on technical capabilities, but on its commitment to customer relationships. The company uses a Customer Focus Team (CFT) model to ensure every client receives dedicated support. These teams oversee quoting, DFM/DFT, NPI, engineering change orders, forecasting, supply chain exposure, and quality reviews.

By maintaining close alignment with customer needs, NEOTech provides responsiveness and flexibility, which are qualities that set it apart from larger Tier 1 EMS providers that often struggle with smaller, more customized engagements.

The NEOTech Advantage

The EMS landscape is divided between smaller, niche providers that offer flexibility but limited scale, and large Tier 1 companies with global reach but rigid processes. NEOTech bridges this gap, offering the best of both worlds.

The EMS landscape is divided between smaller, niche providers that offer flexibility but limited scale, and large Tier 1 companies with global reach but rigid processes. NEOTech bridges this gap, offering the best of both worlds.

Customers benefit from:

• Tier 1 infrastructure and toolsets: global facilities, advanced MES systems, and supply chain leverage.

• Flexibility and responsiveness: ability to adapt processes and terms for customers of varying size and need.

• Multi-site solutions, including cost-effective geographies.

• A wide capability range from prototyping to volume production, from microelectronics to complete system integration.

This positioning makes NEOTech ideal for OEMs that need a partner capable of managing complexity without sacrificing agility.

Conclusion

In every market it serves, NEOTech strives to provide electronics manufacturing solutions for advanced technology OEMs. With its combination of engineering expertise, lifecycle services, high-reliability manufacturing, and customer-first approach, NEOTech has become more than just an EMS provider. It is a strategic partner helping the world’s leading OEMs innovate, manufacture, and sustain products that define modern life, safety, and progress.

From the skies above to the medical devices that save lives, from industrial innovation to space exploration, NEOTech continues to deliver excellence with the flexibility and vision required in today’s complex global environment.

For more information about how NEOTech, contact Steve Bates, Marketing Manager, at steve.bates@neotech.com or visit www.neotech.